Gretsch-Unitas

The Gretsch-Unitas group of companies consists of more than 50 production and sales companies in 35 countries. With the leading international brands G-U (mechanisms/components), BKS (locks, locking systems) and FERCO (mechanisms/components) it offers security technologies.

With a staff of approximately 3,700 people and a tradition of more than 100 years, approximately 30,000 items from the fields of window and door technology, automatic entry systems as well as building management systems are manufactured and marketed.

HISTORY

The history of Gretsch-Unitas begins in 1907, with the idea-rich technician Viktor Gretsch and the manufacture of string skylights, window locking arms and small mechanisms. Three years later, he appoints the merchant Johann Maus as partner and managing director. From the descendants Julius Maus von Resch and Hans Maus, the business evolved into an international enterprise. Brothers Julius and Michael von Resch run the Gretsch-Unitas group of companies today in the 3rd generation. In the 1920s and early 1930s, the company developed more than 120 patents and marketed its successful products throughout Europe. After difficult times, the reconstruction and subsequent relocation of the business from Stuttgart to Ditzingen is achieved. In the mid-70s, the expansion of the company into a business group follows: first with the purchase of the largest French frame mechanism manufacturer FERCO, later with the purchase of the leading lock brand BKS and with the establishment of proprietary service companies. This creates a strong group with high quality, compatible products and services in the fields of windows, doors, entry systems as well as building management.

Hardware

The hardware moves around the perimeter of the leaf and has multiple locks, unlike older mechanisms where the leaf had few locks connected with an aluminum string. Today it is almost always certain that when we talk about hardware we mean G-U (Gretsch-Unitas). Intelligent technical solutions, forming an intelligent system: All the components of the hardware are precisely adapted to each other and designed with the aim of ease of adjustment and handling. It is also possible to realize special shapes, such as for example arched and curved.

The G-U program has 2 basic multi-lock hardware systems for which you can buy parts or spare parts from our online store, quickly and easily:

Sash Rectifier

Raises the sash and secures the recline, supporting user-friendly operation and correct handling.

Tap Adjustment

Double adjustable locks for the pressure of the leaf on the case (±1mm), with Allen key either 4mm or 6mm

Adjustment Cleverle

It automatically compensates for clearance (±1mm), simplifying installation and maintenance.

(exclusively on Uni-Jet)

UNI-JET

D, M, S, C

UNI-JET

SCF, CC

High Aesthetics

UNI-JET Concealed

It meets high demands in terms of design, comfort and handling, opening up new possibilities for window configuration and design. Thanks to the completely hidden hinges, no holes are made in the frame, the visual reference point is now the window itself offering an elegant overall appearance with clean lines in the architectural design while providing the same functionality and safety.

Long Lasting Durability

Protection ferGUard

Basic Surface Treatment

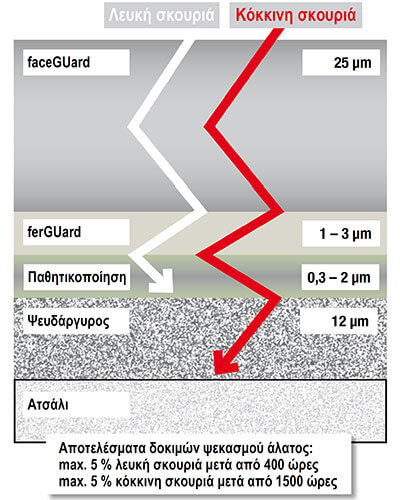

All G-U mechanism parts have a special ferGUard nanotechnology coating that effectively protects them from environmental influences, ensuring long-term flawless operation and appearance. This involves electroplating the base material, passivating it with nanoparticles and then optically sealing it.

- It has a unique self-healing ability in case of minor scratches.

- Nanoparticles make the surface extremely resistant to strong chemicals (plasters, cements, paints, varnishes, strong cleaners, etc.).

- It shows “extremely high resistance to red rust” and therefore exceeds many times what is required by the standard DIN EN 13126/8 Class 4 according to EN 1670: 2007 (D).

- It does not contain organic components, heavy metals or chromium (VI) compounds, and is therefore environmentally friendly and harmless to health.

- It offers an attractive uniform silver look to all components. The requirements for the mechanisms are defined in the RAL of opening and tilting window mechanisms (RG 607/3) and RAL of galvanized products (GZ 660 Part 1 and 2).

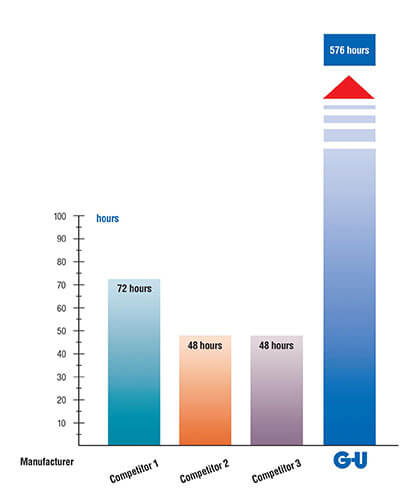

The mechanisms are in this case classified in strength scale 3. This strength scale requires an average thickness of 12mm of zinc (galvanizing). The components shall withstand the rust test according to DIN 50021 SS (in salt water) for 72 hours, until the beginning of the appearance of rust. Basic rust on the mechanism (red rust) should appear no earlier than 240 hours.

The superiority of ferGUard technology was demonstrated in tests conducted at the Steinbeis Transfer Center of Surface and Environmental Technology in Aalen, Germany, between different mechanism companies. Counting the hours to white rust, the G-U Uni-Jet engine performed the best at 576 hours, clearly outpacing all other companies by far.

Protection faceGUard

Additional Surface Treatment

It is applied in addition to the basic ferGUard protection, exclusively at the customer’s request and only in the UNI-JET system. Each individual component is coated with a special high-tech ceramic coating. It is used for maximum resistance in extreme atmospheric conditions where corrosion is more aggressive, such as in coastal areas with high concentrations of sodium chloride (salt), in heavy industrial areas with high pollution, in swimming pools with chlorine/ozone fumes, in animal stables with formation of heavy ammonia gas etc.

- Maximum corrosion protection for long-term functionality and durability under extreme conditions.

- Even more resistant to aggressive acids, gases and alkalis (plasters, cements, paints, varnishes, strong cleaning agents, etc.).

- It exhibits extremely high corrosion resistance under extremely difficult conditions and therefore exceeds by many times what is required by DIN EN 13126/8 Class 5 (highest class) according to EN 1670: 2007 (D).

- It offers an attractive uniform matte gray appearance to all components.

Burglary Protection

RC1

For hard-to-reach windows, Basic Security is sufficient with protection mainly against vandalism and break-in attempts with physical violence such as body, shoulder or kick attacks.

RC2

For easily accessible windows, Medium Security protects against break-in attempts with simple tools such as pliers, pliers, screwdrivers and wedges. It is the main choice of the majority of constructions.

RC3

For very easy-to-access windows. Provides High Protection against the use of a second screwdriver, crowbar or “bitch” as well as additional puncture protection. We recommend that this option be combined with safety glass.